Digitization of industrial processes at SOLVAY

Solvay is an advanced materials and specialty chemicals leading company. Based in Brussels, it has more than 26,000 employees and a presence in over 50 countries.

Customer:

Sector:

CHEMISTRY INDUSTRY

Location:

GLOBAL

THE PROJECT

At every factory of the company, dozens of control and supervision procedures are carried out daily which are inherent to their industrial activity. These procedures are required to control production, but also to assure the workers’ safety, the quality of raw materials used in the production process and the breakdown of machinery prevention.

With the objective of simplifying and facilitating the development of these procedures, Evenbytes has accompanied these processes with a digitalization project that saves time and money to solvay. Moreover, it improves quality and reduces the environmental footprint by removing paper documents. It also ensures the reliability of the gathered data.

METODOLOGY

Digitalization focused on the user

Focusing on control and prevention processes at one single factory, we must take into account that it is working 24/7. This is the main reason why they need to carry out preventive recognitions periodically in order to avoid breakdowns that may affect the production process. Furthermore, the checks on working security and raw materials quality are also crucial.

One of the main objectives was integrating the digitalization of every process without having a big impact on the work of people in that area. It was necessary to perfectly understand how each process was carried out, when and which data was collected before their digitalization. In addition, it was the right time to add all the lacks they previously had, as from that moment onwards all the data was going to be ready for use in real time.

CHALLENGES

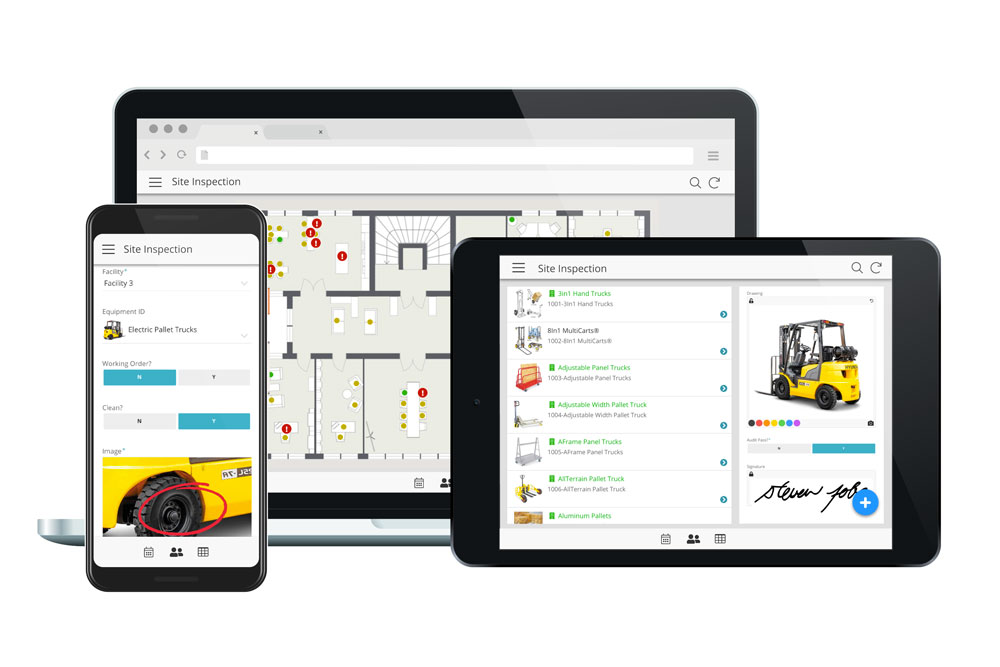

Mobile & Offline first

One of the main challenges when digitalizing these processes was the fact that many mobile devices that were already being used at the factory did not have 4G connexion. Those devices only had internet connection through Wi-Fi when they were at certain offices, but not at the rest of the factory. So, it was necessary that the apps worked also offline and were able to synchronize when they reached a connection point.

Another problem that we faced was that the forms of some preventive checks were from 10 to 50 paper sheets long, so the app had to compile more than 10,000 values and generate a report with them. So, it was necessary to simplify the data gathering.

ANALISYS

The power of data

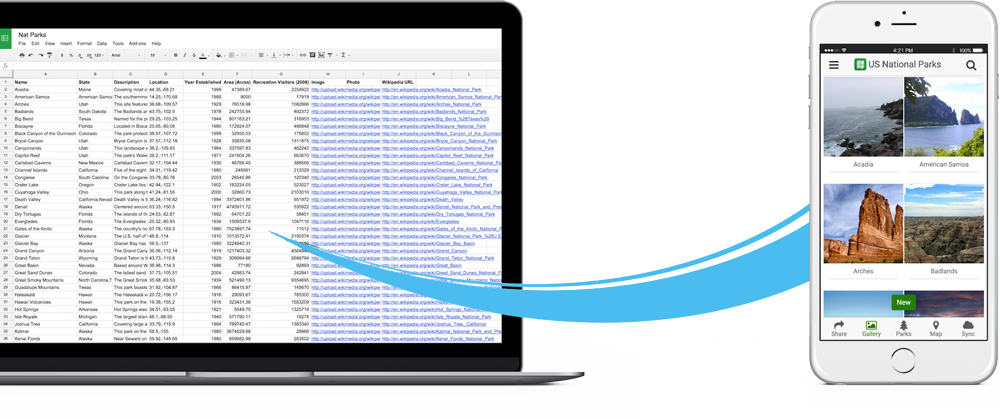

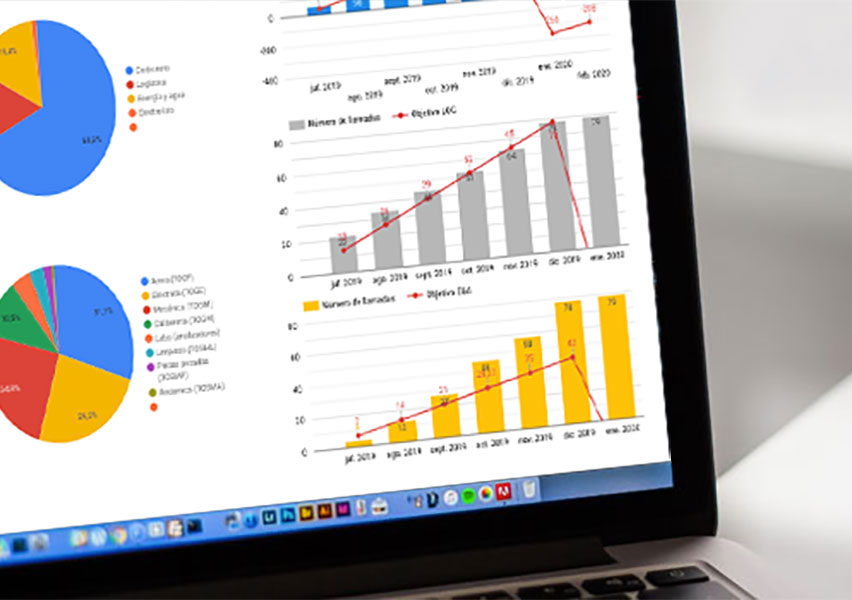

Thanks to the obtention of data in real time and its convenient availability at Google Sheets, it was possible for some departments to configure visualization and operation dashboards of the data with statistics and metrics.

This reports allow a quick and easy interpretation of data, so managers can take decisions in a more effective way.

SOLUTION

After several meetings with different departments, the idea was changing the data gathering form paper to smartphone or tablet, always maintaining the context of each collected parameter in order to facilitate the work of people that is going to use this apps.

Every mobile application use Google Spreadsheet as data storage. This allows to have access to the data at any moment, analyze and exploit results through the configuration of several Data Studio.

Every application automatically generates a report with the data gathered by the worker and is immediately sent to the managers of that area, so they are able to respond quickly if needed.

For some applications it was also necessary to develop approval flows ir order to simplify and optimize communication among managers and/or departments.

RESULTS

We have developed more than 20 specific applications for different departments at the factory (security and environment, industrial maintenance, quality, logistics and production).

More than 120 procedures have been digitalized, some of them with direct implication for the entire working regarding employees and external suppliers.

The time employed to the data collection and filing process was considerably reduced, with the corresponding money saving and quality improvement.

Currently, the indicators of the revisions and automation in real time of alerts and warnings, are updated immediately according to the readings obtained by the operators.

This has made the access to documents related with machinery easier, which facilitates maintenance work and saves time.

The reduction of paper has been almost complete for these processes.

SDG that benefit from this project

In Evenbytes we are committed with the sustainable development goals. We believe that technology can help improving our quality of life. That is why we try to contribute with all our knowledge, always taking into account the environment.

ARCHITECTURE